Welcome to the website of Zibo Fanruike Trading Co., Ltd. !

Welcome to the website of Zibo Fanruike Trading Co., Ltd. ! Welcome to the website of Zibo Fanruike Trading Co., Ltd. !

Welcome to the website of Zibo Fanruike Trading Co., Ltd. !Company:Zibo Fanruike Trading Co., Ltd.

Contacts:Manager Chen

Mobile:15106439852

Mailbox:15106439852@163.com

Address:800 meters west of the Village Committee of Zhujia Village, Lingzi Town, Zichuan District, Zibo City, Shandong Province

1. Product Introduction

Product Description:

A new type of refractory lining product is introduced to simplify and speed up the construction of kilns and improve the integrity of the lining. This product is white in color and regular in size. It can be directly fixed on the anchor nails of the steel plate of the industrial kiln shell. It has good refractory and heat insulation effects, improves the integrity of the kiln refractory and heat insulation, and promotes the progress of kiln masonry technology. Classification temperature 1050-1400℃

Features:

Excellent chemical stability; excellent thermal stability; excellent elasticity, the module is in a pre-stressed state. After the furnace lining is built, the expansion of the module makes the furnace lining seamless and can compensate for the contraction of the fiber lining to improve the insulation performance of the fiber lining, with good overall performance; excellent thermal stability and thermal shock resistance; the ceramic fiber module is installed quickly, and the anchor is set on the cold surface of the wall lining, which can reduce the requirements for the material of the anchor.

typical application:

Lining insulation of kilns in the petrochemical industry; Lining insulation of kilns in the metallurgical industry; Lining insulation of kilns in the ceramic, glass and other building materials industries; Lining insulation of heat treatment furnaces in the heat treatment industry; Lining insulation of other industrial kilns.

Serve:

We can provide insulation design and construction training according to the different furnace types of customers.

2. Advantages of modules in industrial kilns

At present, the overall module made of compressed aluminum silicate ceramic fiber blanket is gradually becoming the preferred refractory material for thermal insulation of modern industrial furnace lining due to its many advantages such as high temperature resistance and easy construction.

Over the past few years, the wide application of this product in the fields of petrochemical, steel, electricity, cement, etc. has enabled us to accumulate valuable construction experience; our one-stop service of technical support, material recommendation and quality tracking has won full recognition from authoritative departments and a wide reputation in the industry.

Features:

1. During the installation process, the folded blankets will generate huge stress after being untied, and they will be crowded and closed without any gaps;

2. The high elasticity of the fiber blanket can make up for the deformation of the furnace shell and reduce the construction cost. At the same time, it can make up for the gaps between different components inside the furnace body due to different thermal changes;

3、 Due to its light weight and low heat capacity (only 1/10 of that of lightweight heat-resistant lining and lightweight refractory bricks), it can significantly reduce energy consumption in furnace temperature operation control;

4. Elastic fiber blanket can resist mechanical external force;

5. Ability to resist any thermal shock;

6. The lining does not need to be dried or maintained, and the furnace can be put into use after the lining construction is completed;

7. Stable chemical properties. Except phosphoric acid, hydrofluoric acid and strong alkali, other acids, alkalis, water, oil and steam will not corrode it.

3. Performance characteristics of refractory fiber products Refractory fiber, also known as ceramic fiber, is currently the refractory material with the lowest thermal conductivity and the best thermal insulation and energy-saving effect except for nanomaterials. It has many advantages such as light weight, high temperature resistance, good thermal insulation effect, and convenient construction. It is a high-quality industrial furnace lining material. Compared with traditional refractory bricks, refractory castables and other materials, refractory fiber materials have the following performance advantages: a) Light weight (reducing kiln load and extending furnace life): Refractory fiber is a fibrous refractory material. The most commonly used refractory fiber blanket has a volume density of 96-128Kg/m3, while the volume density of the refractory fiber module folded from the fiber blanket is between 200-240 Kg/m3, and the weight is 1/5-1/10 of lightweight refractory bricks or amorphous materials, and 1/15-1/20 of heavy refractory materials. It can be seen that refractory fiber lining materials can achieve lightweight and high efficiency of heating furnaces, reduce kiln loads, and extend furnace life. b) Low heat capacity (less heat absorption, faster heating): The heat capacity of the furnace lining material is generally proportional to the weight of the furnace lining. Low heat capacity means that the kiln absorbs less heat during reciprocating operation and heats up faster. The heat capacity of ceramic fiber is only 1/10 of that of lightweight heat-resistant lining and lightweight refractory bricks, which greatly reduces the energy consumption in furnace temperature operation control, especially for intermittent heating furnaces, which has a very significant energy-saving effect.

c) Low thermal conductivity (low heat loss): The thermal conductivity of ceramic fiber materials is less than 0.06W/mk at an average temperature of 200 ℃, less than 0.10W/mk at an average temperature of 400 ℃, which is about 1/8 of that of lightweight heat-resistant amorphous materials and about 1/10 of that of lightweight bricks. However, the thermal conductivity of ceramic fiber materials can be ignored compared to heavy refractory materials. So the insulation effect of refractory fiber materials is very significant.

d) Simple construction (no need to leave expansion joints): Construction personnel can take up their posts after basic training, and construction technical factors have little impact on the insulation effect of the furnace lining. e) Wide range of use: With the development of refractory fiber production and application technology, refractory ceramic fiber products have achieved serialization and functionalization. The products can meet the use requirements of different temperature levels from 600℃ to 1400℃ in terms of use temperature. From the perspective of form, secondary processing or deep processing products in various forms have gradually been formed from traditional cotton, blankets, and felt products to fiber modules, boards, special-shaped parts, paper, fiber textiles, etc. It can meet the use requirements of refractory ceramic fiber products in different industrial furnaces in various industries. f) Thermal shock resistance: The fiber folding module has particularly good resistance to severe temperature fluctuations. Under the premise that the heated material can withstand it, the fiber folding module furnace lining can be heated or cooled at any speed. g) Mechanical vibration resistance (flexible and elastic): The fiber blanket or felt is flexible and elastic, and not easy to break. The installed integral furnace is not easily damaged when it is impacted or vibrated by road transportation.

h) No need for oven: No need for oven procedures (such as maintenance, drying, baking, complex oven processes, and protective measures in cold weather), the furnace lining can be put into use after construction is completed. I) Good sound insulation performance (reducing noise pollution): Ceramic fibers can reduce high-frequency noise with a frequency of less than 1000 Hz. For sound waves with a frequency of less than 300 Hz, their sound insulation ability is superior to commonly used sound insulation materials, and can significantly reduce noise pollution. j) Strong automation control ability: The high thermal sensitivity of ceramic fiber furnace lining can better adapt to the automation control of heating furnaces. k) Chemical stability: The chemical properties of ceramic fiber furnace lining are stable, and except for phosphoric acid, hydrofluoric acid, and strong alkali, other acids, alkalis, as well as water, oil, and steam are not corroded.

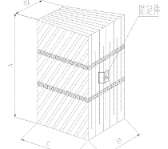

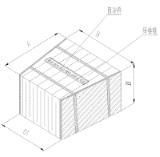

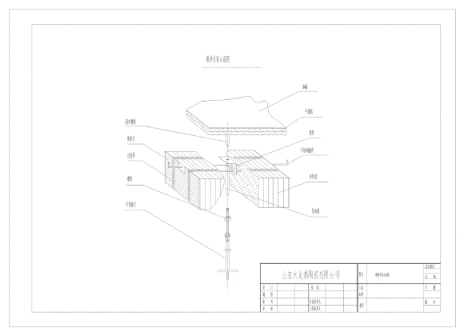

Module structure drawing

Modules for furnace walls Modules for furnace hoods

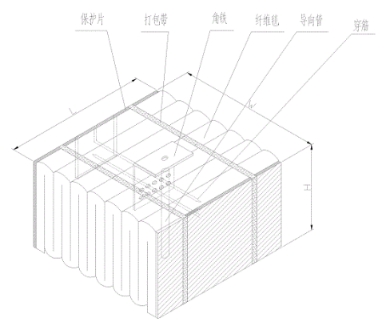

Angle iron modular structure

Module installation instructions

Contact us

Contact number:

Contact email:15106439852@163.com

Address:800 meters west of the Village Committee of Zhujia Village, Lingzi Town, Zichuan District, Zibo City, Shandong Province

15106439852

National customer service hotline